Challenges and solutions of reducing porosity formation during remote laser welding of die casting aluminium | Laser Systems Europe

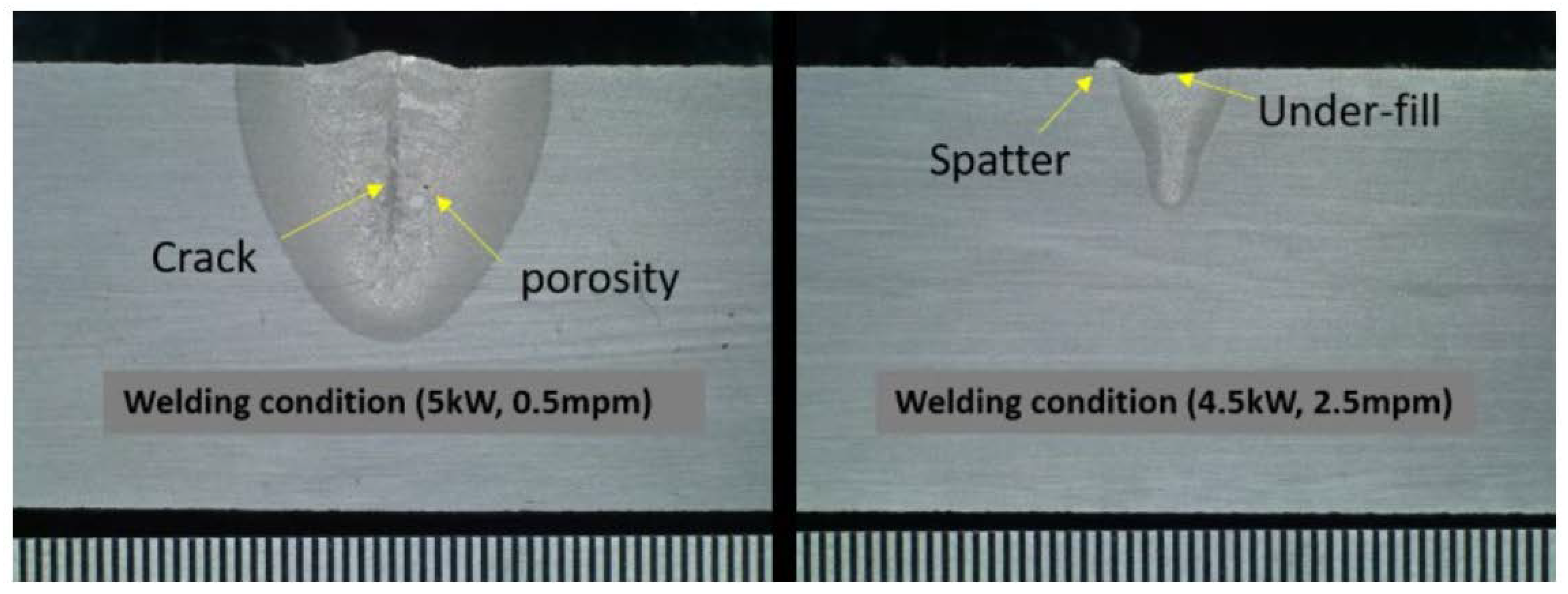

Metals | Free Full-Text | Laser Welding of ASTM A553-1 (9% Nickel Steel) (PART I: Penetration Shape by Bead on Plate)

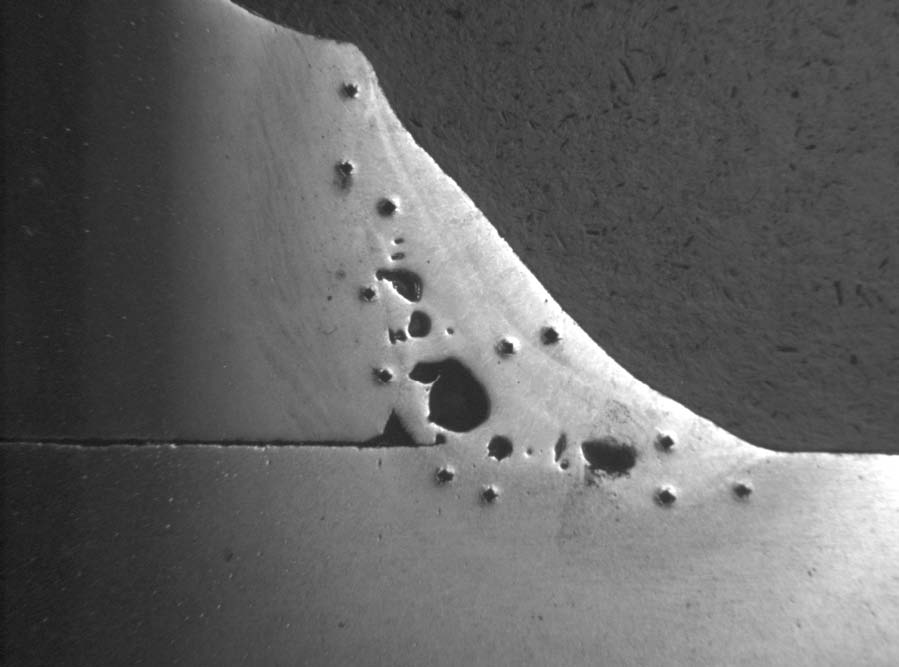

Comparison of pores produced in laser welding of Ti6Al4V (a) with those... | Download Scientific Diagram

Challenges and solutions of reducing porosity formation during remote laser welding of die casting aluminium | Laser Systems Europe

Applied Sciences | Free Full-Text | High-Speed X-Ray Investigation of Pore Formation during Full Penetration Laser Beam Welding of AA6016 Aluminum Sheets Contaminated with Lubricants

Study on porosity formation in laser welds in aluminium alloys (Report 1): Effects of hydrogen and alloying elements

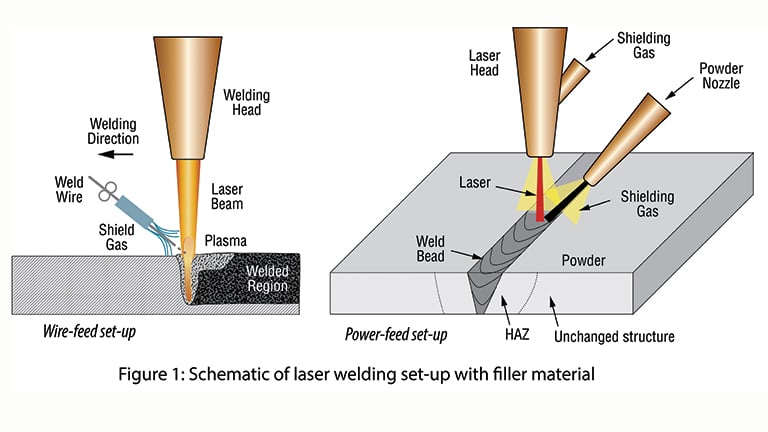

Laser Beam Welding of Austenitic Stainless Steels – Similar Butt and Dissimilar Lap Joints | IntechOpen

Challenges and solutions of reducing porosity formation during remote laser welding of die casting aluminium | Laser Systems Europe

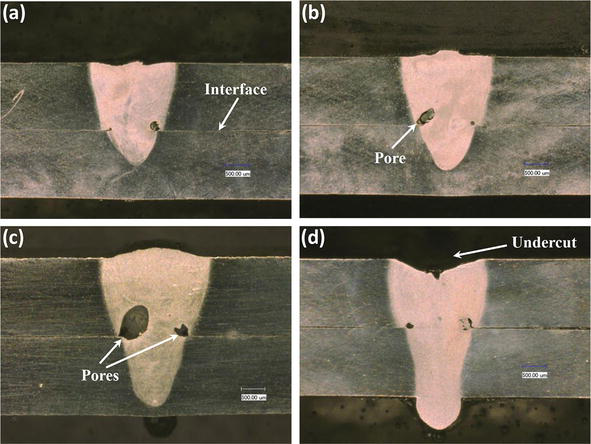

Porosity in longitudinal sections of butt-welded specimens: ( a ) PW1,... | Download Scientific Diagram

Area-percent porosity produced in laser welds of AM60B alloy at several... | Download Scientific Diagram

Study on the distribution, element characteristics, and formation mechanism of porosity during laser welding for Ti-6Al-4V bottom-locking joint | SpringerLink

Porosity reduction and elimination in laser welding of AA6014 aluminium alloys for automotive components manufacture and industrial applications | Semantic Scholar

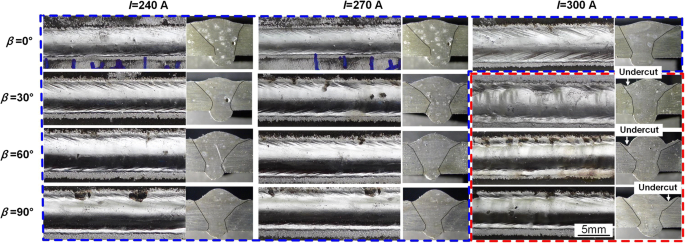

Influence of welding angle on the weld morphology and porosity in laser-arc hybrid welding of AA2219 aluminum alloy | SpringerLink

![PDF] Effects of Laser Parameters on Porosity Formation : Investigating Millimeter Scale Continuous Wave Nd : YAG Laser Welds An evaluation of the role continuous wave laser process parameters has on pore PDF] Effects of Laser Parameters on Porosity Formation : Investigating Millimeter Scale Continuous Wave Nd : YAG Laser Welds An evaluation of the role continuous wave laser process parameters has on pore](https://d3i71xaburhd42.cloudfront.net/1d168ef4b6ac9fe0b5731da962d3ab83830f96ac/3-Figure4-1.png)